Ball Mill Of Mineral

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral

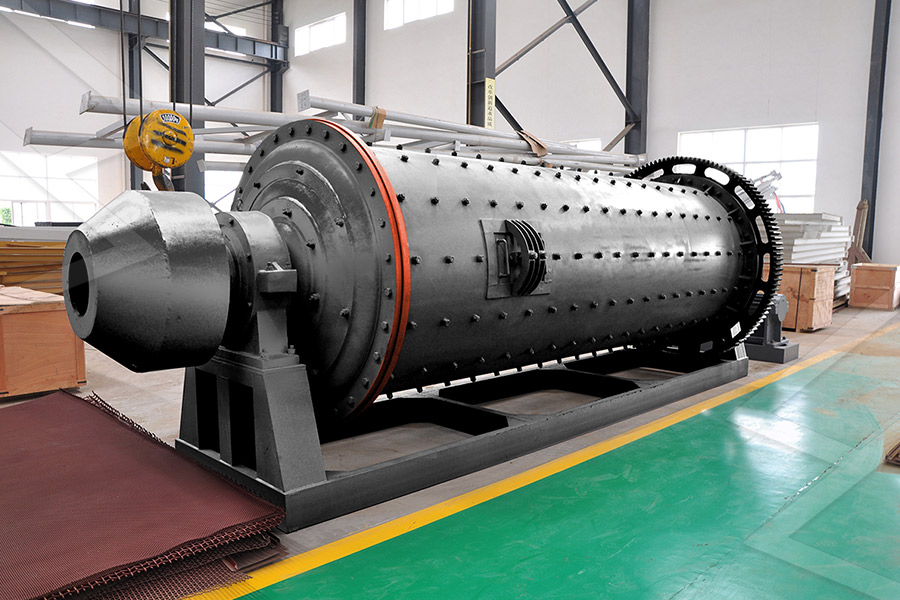

2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the Feature papers represent the most advanced research with significant Versions NotesBall mill grinding machines are widely used in various industries for the comminution of materials into fine powders They are versatile tools that offer efficient and reliable grinding and mixing capabilitiesBall Mill Grinding Machines: Working Principle, 2023年11月24日 The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and Grinding Media in Ball Mills for Mineral Processing2024年12月4日 A gold ball mill is a type of grinding mill used in the mining industry to crush and grind gold ore into finer particles It is an essential component of the gold extraction process, as it helps to liberate gold from the The Gold Ball Mill: A Crucial Tool in Gold Ore Ball mills are the most common grinding machine employed in the mining industry Grinding occurs in a single stage, or multiple stages Multiple stages may include a rod mill followed by a ball mill (two stage circuit), or a semi Ball Mill (Ball Mills Explained) saVRee saVRee

Ball Mills in the Mineral Processing Industry

2024年5月27日 Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc They fall part of the comminution process, where ores are crushed to separate valuable Ball mills are pivotal in mineral processing to achieve the desired product quality Whether for raw material grinding or final product grinding, we use Ball Mills extensively to reduce the size of hard minerals, such as ores, limestone, and Advanced Technology Ball Mills for Mineral Our Ball mills are designed for mining and mineral processing industry, for grinding the ore to the expected size for the next stage beneficiation process We also supply the laboratory and pilot Ball Mills – ZJH minerals2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materialsA Review of the Grinding Media in Ball Mills for 2025年3月1日 What is a Ball Mill? A ball mill is a mechanical device designed for grinding materials into finer particles It consists of a horizontally rotating drum that contains grinding Understanding Ball Mills: Principles, Design, and Applications2002年11月1日 This value of ball mill efficiency can be compared with those of Fuerstenau and Kapur (1994), Schoenert (1972) and Carey and Stairmand (1952) who reported values of The energy efficiency of ball milling in comminution

3 Common Problems and Solutions in Ball Mill

2020年6月24日 The stable operation of equipment is an important way to ensure the economic benefit of mineral processing plants Due to longterm operation, ball mills of most mineral processing plants will cause various 2025年2月18日 High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG Grinding Mills Mineral Processing Equipment5 天之前 DOVE Ball Mills are used in hard rock mineral processing plants as an oredressing step to grind the rocks into fine powder size, liberating the mineral particles from the rocks Ball Mill Ball Mills Wet Dry Grinding DOVE2013年8月1日 Apart from these cost factors, one of the major unsolved problems in the optimal design of ball mills concerns the equilibrium media size distribution in the mill, which is Consumption of steel grinding media in mills – A review2019年8月14日 At this time, it is necessary to replace the new ball mill liner The ball mill liner is intended to protect the barrel of the ball mill in order to reduce and avoid direct impact and The Ultimate Guide to Ball Mills Miningpedia2024年3月7日 Dry ball mills offer extensive application prospects within the mineral processing process, promising enhanced production efficiency, cost reduction, and advancements in Application of Dry Ball Milling in Mineral Processing

.jpg)

Highquality Ball Mill with Low price for Kinds of Materials

1 天前 Wet ball mills are commonly used in mineral processing and usually have a singlechamber structure Difference: The key difference between dry ball milling and wet ball milling 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the A Review of the Grinding Media in Ball Mills for Mineral 2001年8月1日 Ball mills are used in mineral processing for particle size reduction These consist of a rotating cylindrical shell of up to 7 m in diameter with axial lengths greater than this Lifter Charge behaviour and power consumption in ball mills: Our Metso Premier™ mills and Select™ mills are supported by our comprehensive services network to ensure optimization during your mills lifetime Also the Premier™ mills and Select™ mills come ready to be easily integrated Grinding mills for mining and minerals 2025年1月27日 Horizontal ball mills are the most commonly used type in industrial applications These mills feature a cylindrical shape and are typically mounted horizontally, with the material and grinding media moving in a rotary Types of Ball Mills: A Comprehensive Guide to 2017年9月1日 The dominant breakage mechanism in ball mills is generally considered to be impact breakage in the toe of the mill, The objective of this work is to assess the influence of Fine grinding: How mill type affects particle shape characteristics

.jpg)

Understanding the mechanism: How does a ball mill work?

2024年10月13日 Mineral Processing: Ball mills are widely used in mineral processing industries for the grinding and separation of ores They are essential in the preparation of ore for 2024年4月24日 Ball mills are particularly useful in mineral processing, paints, pyrotechnics, and ceramics, where achieving a specific particle size is essential The efficiency and simplicity of What is a Ball Mill? Exploring the Uses and Functionality of Ball Mill Applications of ball mills and agitated media mills Ball mills have been used to produce highquality mineral flours for many years They are suitable for grinding mediumhard to extremely Ball Mills Agitated Media Mills Hosokawa Alpine2012年6月1日 Scale Ball Mill – Minerals Engineering, V ol 22, 2009, 660664 19 F u e r s t e n a u, D W, A Z M A b o u z e i d The Energy Efficiency of Ball Milling in Ball mills can (PDF) Grinding in Ball Mills: Modeling and Process Control2023年11月24日 The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and Grinding Media in Ball Mills for Mineral Processing2024年12月12日 What Is a Ball Mill? A ball mill is a grinding machine designed to reduce materials into an extremely fine powder It consists of a hollow cylindrical shell that rotates around a horizontal axis Inside the cylinder, you’ll What Is a Ball Mill? Understanding How It Works,

Bond´s work index estimation using nonstandard ball mills

2023年9月18日 The traditional Bond work index proposed by FC Bond over 60 years ago is still today a useful tool for characterizing material crushability and grindability in the minerals industry2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 Grinding Mills Common Types 911Metallurgist2004年9月1日 The proposed model, combined with a model giving the ballmill power draw, is used for the ballmill scale up Comparisons with the Bond procedure showed a good Modelling the Specific Grinding Energy and BallMill Scaleup2004年12月10日 The ball mill has an inside diameter (inside liners) of 072 m Its length can be varied by combining different tube shells with a length of 25 or 50 cm in the range of 125–35 Optimization of continuous ball mills used for finishgrinding 2013年4月1日 In mineral processing, ceramic balls have first been applied in secondary mill of the twostage grinding circuit, showing great positive effect on the grinding process The ball Closed circuit ball mill – Basics revisited ScienceDirect2003年5月7日 steel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the operating charge Let Jt be the TECHNICAL NOTES 8 GRINDING R P King Mineral Tech

PROCESS OPTIMIZATION OF A SMALL SCALE BALL MILL

2019年8月6日 BALL MILL FOR MINERAL PROCESSING USING DISCRETE ELEMENT METHOD PHILBERT MUHAYIMANA MASTER OF SCIENCE (Mechanical Engineering) 2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell What is a Ball Mill Explained: InDepth Guide JXSCFLS Ball mills deliver high throughput ore grinding with impressive energy efficiency, helping you maximise mineral recovery and reduce TCO Even better, our advanced process control Ball Mills – efficient grinding FLS FLSmidth2002年11月1日 This value of ball mill efficiency can be compared with those of Fuerstenau and Kapur (1994), Schoenert (1972) and Carey and Stairmand (1952) who reported values of The energy efficiency of ball milling in comminution2020年6月24日 The stable operation of equipment is an important way to ensure the economic benefit of mineral processing plants Due to longterm operation, ball mills of most mineral processing plants will cause various 3 Common Problems and Solutions in Ball Mill 2025年2月18日 High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG Grinding Mills Mineral Processing Equipment

.jpg)

Ball Mill Ball Mills Wet Dry Grinding DOVE

5 天之前 DOVE Ball Mills are used in hard rock mineral processing plants as an oredressing step to grind the rocks into fine powder size, liberating the mineral particles from the rocks 2013年8月1日 Apart from these cost factors, one of the major unsolved problems in the optimal design of ball mills concerns the equilibrium media size distribution in the mill, which is Consumption of steel grinding media in mills – A review2019年8月14日 At this time, it is necessary to replace the new ball mill liner The ball mill liner is intended to protect the barrel of the ball mill in order to reduce and avoid direct impact and The Ultimate Guide to Ball Mills Miningpedia2024年3月7日 Dry ball mills offer extensive application prospects within the mineral processing process, promising enhanced production efficiency, cost reduction, and advancements in Application of Dry Ball Milling in Mineral Processing1 天前 Wet ball mills are commonly used in mineral processing and usually have a singlechamber structure Difference: The key difference between dry ball milling and wet ball milling Highquality Ball Mill with Low price for Kinds of Materials2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the A Review of the Grinding Media in Ball Mills for Mineral